Transforming Paving with Concrete Block Permeable Overlays

Low-intervention permeable paving overlays can transform worn-out paving and deliver SuDS, green infrastructure and healthy streets. To understand how, it’s worth reminding ourselves of the unique characteristics and attributes of modular concrete paving generally.

Concrete Block Paving

This long-established technology is based on high-strength, interlocking units installed with granular material filled joints and laying course. It enables small displacements between blocks, while retaining interlock, to create a particularly durable wearing course over structural layers below and forming a ‘flexible pavement’. Decades of use internationally have demonstrated its suitability for the most taxing paving applications. A wide choice of shapes, styles, colours and finishes – including natural aggregates – add a richness, diversity, visual interest and a human scale to the urban realm.

Concrete Block Paving is slip resistant, durable, strong and sustainable. Modular concrete paving delivers fast, low-cost installation using weather-independent, ‘dry’ construction methods. There are no curing, hot-work or noxious fumes problems and only small plant and equipment is needed, with noise and disturbance minimised. With an extremely long lifespan, blocks can be taken up and re-used without processing for repairs, changing demands and layouts, or new schemes – saving carbon and meeting ‘circular’ economy’ criteria.

Permeable Paving

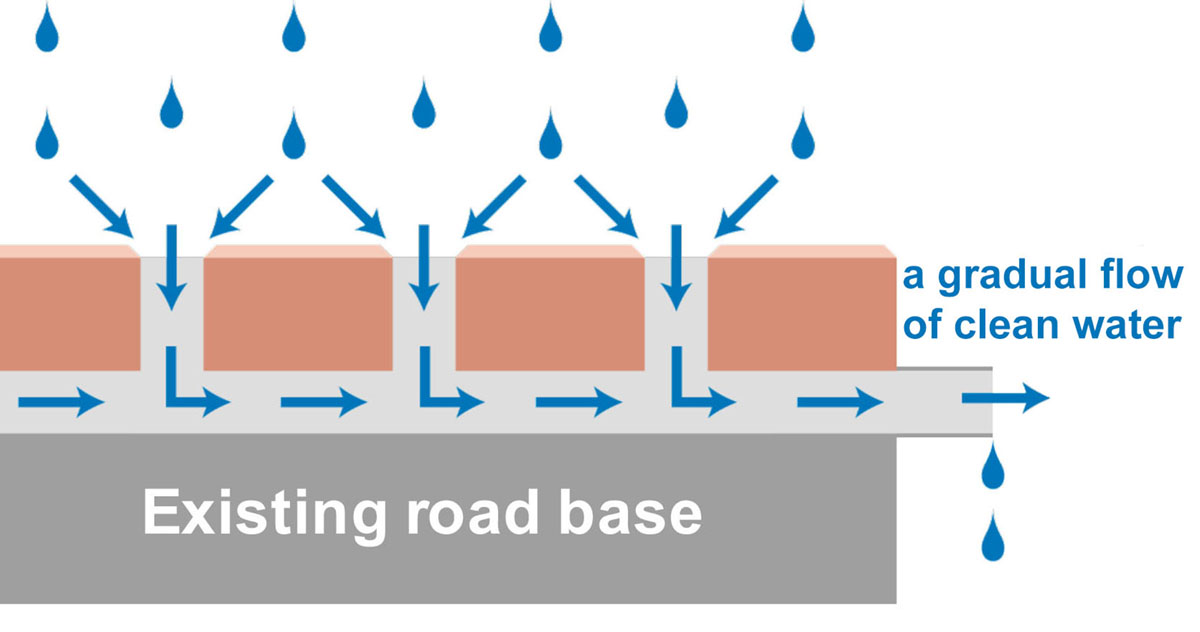

Concrete Block Permeable Paving (CBPP) enhances this technology as a well-established, multi-functional SuDS technique. It simply combines self-drained, safe and attractive surfaces for a wide range of applications with attenuation, storage, pollution treatment and conveyance of rainwater runoff. The difference with CBPP is angular aggregate (2/6.3mm) – not sand – used to fill enlarged joints and as a laying course. Then, pavement layers of voided material (typically 4/20mm) below accommodate water, whilst still providing the required structural performance. CBPP can also accept runoff from adjacent impermeable paving and roofs up to twice its own area.

By its very nature, CBPP requires no additional land-take for water storage or management, and no gulleys with related pipework. Its unique capabilities include source control and delivering a gradual flow of clean water to open SuDS features, for amenity or biodiversity, to drainage systems or into the ground. More than 25-years usage has proven it to be a robust, resilient and adaptable technology, used on projects ranging from footpaths to container terminals, with the reassurance of proven engineering design solutions. Both construction and whole-of-life costs of CBPP have been shown to be lower than for conventional paving and drainage, and it requires only limited, straightforward maintenance without clogging problems. It’s important to remember that CBPP is unlike – and not to be confused with – permeable materials, which behave very differently.

Paving Overlays

Concrete Block Permeable Paving Overlay is a deceptively simple, innovative approach to retrofitted CBPP, delivering SuDS as part of low-intervention asset renewal or regeneration. The CBPP upper layer is simply applied as an overlay replacing planed-off old asphalt or other road surface, onto the original structural road base. In many cases, this can simply run kerb-to-kerb to form a shared surface level with the footway and flush kerb top. This approach also enables low-cost improvement works – perhaps linked to ‘Healthy Streets’, new Highway Code measures, or as part of creating traffic calming, Low Traffic Neighbourhoods or Homezones.

The same blocks and 2/6.3mm grit bedding layer and jointing material as for permeable pavements generally are used. Water is attenuated, treated and conveyed within the laying course, which is key to this technology, enabling filtration of silt and retention/treatment of pollutants without clogging. A gradual flow of clean water can then be released near the surface, meeting SuDS requirements.

This approach provides numerous benefits including:

- Interception losses, managing runoff during regular rainfall events

- Attractive, popular surfaces with no puddles or potholes, for user safety

- Maximising re-use of existing road-base and its embodied carbon

- Optimising the original drainage regime, but below the surface

- Low-intervention, low carbon, no-heat retrofit installation

- Long-life with minimal maintenance and low whole-of-life cost

- No open gulleys – wildlife-safe

- Integral water filtration, with debris/litter remaining on the surface

- Straightforward access to below-ground services

- Sustainable re-use of blocks for reinstatement or changed layouts.

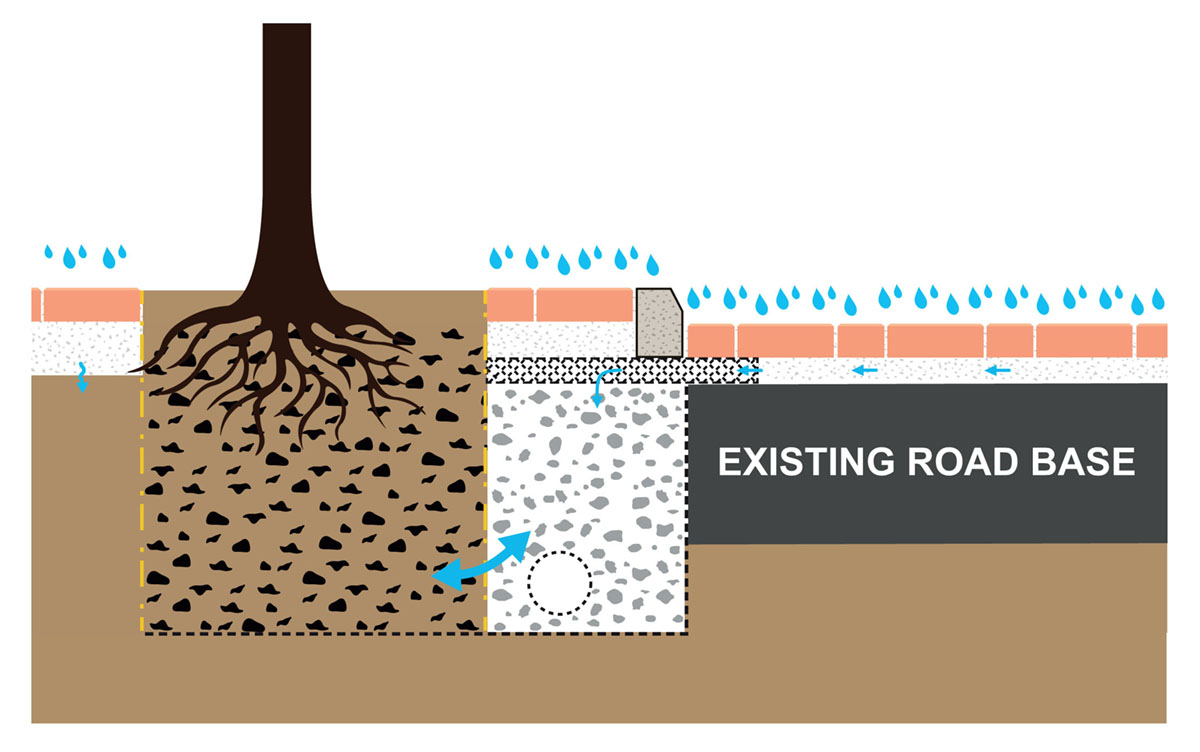

Permeable Paving and Trees in Synergy

CBPP and trees have been proven to work together in synergy. CBPP – whether full-construction or in overlay form – can collect rainfall away from the canopy and convey it to the tree. It can then simply discharge horizontally into a raingarden, perhaps with overflow into an existing adapted gulleys. The raingarden stores water during heavy rain for SuDS, retains soil moisture during dry weather and provides additional water quality ‘polishing’, as well as irrigation. Alternatively, CBPP can be used over standard tree pits, proprietary tree planters, Stockholm System or other structural soil installations, enabling irrigation and simple gas (oxygen/carbon dioxide) exchange essential to trees – without additional reservoirs or pipes. CBPP also avoids tree root disruption common with other paved surfaces.

An exemplar of this technology is the award-winning regeneration project Bridget Joyce Square in Australia Road, White City, London. Interpave revisited the project in August 2021, around 5 years after completion, and noted that the permeable paving was performing well and experienced no problems during recent extreme summer storms, despite extensive flooding nearby. Tests were also carried out demonstrating that all the water infiltration rates of the permeable paving were more than double those recommended by ‘The SuDS Manual’ (CIRIA, 2015). The trees and other green infrastructure were healthy, substantial and particularly well-established.

A case study exploring Bridget Joyce Square is available here. Other innovative project case studies will be published here shortly.